All personnel in the workplace have a duty of care to do everything reasonably practicable to protect others by complying with safe work practices. Having the equipment in your workplace regularly inspected goes a long way to minimise the risk of an injury or accident.

Whether the equipment is located in the workshop or onsite no job is too big or small for STS. Our services are guaranteed, cost effective and efficient.

Eliminate the hazards, minimise the risk and make your workplace a safer environment so everyone can go home at the end of the day.

Electrical Test & Tagging

STS perform onsite electrical safety inspections of portable ''plug in'' electrical equipment in order to identify and eliminate potential hazards. The defective items are either placed “Out of Service”, repaired or replaced. We ensure that your equipment complies with the minimum requirements set out by Australian Standard AS/NZS 3760 and conforms with the WA Occupational Safety and Health Act 1984 Regulations.

Lifting Gear Inspections

Periodic onsite inspections of lifting and rigging gear. These include flexible steel wire rope, synthetic and chain slings and attachments such as swivels, shackles, rings, clamps, eyebolts and hooks. We verify the Safe Working Load (SWL) and examine for any damage. Like the electrical equipment, any defective lifting gear is placed “out of service” or repaired or replaced.

RCD Testing

RCD's also known as safety switches, significantly reduce the risk of electric shock and prevent electrocution by cutting the electricity supply if an imbalance is detected. STS checks the mechanical functionality of the RCD, the trip current and the time it takes to trip (should be in milliseconds). The maximum allowable trip time will vary depending on the facility but most conventional RCD's must trip below 300ms.

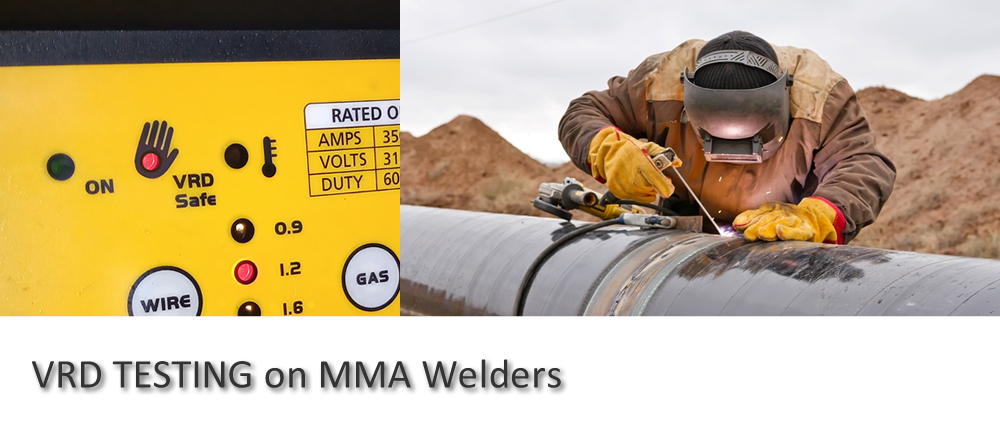

Welder VRD Testing

The electrical circuit of a welder comprises a power source, electrode lead, electrode, work piece, work terminal and work lead. An electric shock may result if a person becomes part of the welding electrical circuit during welding. The Voltage Reducing Device (VRD) built-in into modern Manual Metal Arc (MMA) welders, is a hazard-reducing component that reduces the welders Open Circuit Voltage (OCV) to a safer level. STS provide regular measurements of the OCV of welders and ensure that the VRD is functioning correctly and within Australian Standards.